Yo Ho Ho

Life has been mooey crazy. Emergency vet run with Ringo on Saturday; he was at death’s door but we got the little guy back At first we were afraid he’d had a stroke but after many tests it turns out his thyroid is outta whack and to make matters worse he had trouble breathing what with all the smoke from the fires and him having chronic bronchitis. Glad he’s on the mend. And natch, I didn’t have my cellphone because a pal accidentally took it home with him.

Have also had not one but two computers go down; primary laptop and secondary desktop. Desktop finally set to rights but my brand new Panasonic Toughbook (a resounding two thumbs down!!) is in the shop for the second time. This time it’s getting a complete reinstall of the OS (remember when XP used to be stable? Not if you get the Vista ‘downgrade’ it ain’t!). Trouble is, it’s barfing it back up! Toughbook my ass.

Between catastrophes and with Gothalot doing all the machining I managed to connect the dots and weld up the roof-mounted propane storage rack for the Blood Vessel. Still gotta do all the propane plumbing but that’s fairly straightforward, if a little time intensive. Photos soon.

Sadly I’ve had to lay down the tools on the calliope project as there’s only one week to prove to DMV that I’m doing ‘due diligence’ on Short John Silver. Although I intend for the calliope to be an active part of the thing I can’t spend all of my time tinkering; gotta get a bucket and slap some paint on the old MV, so to speak…

Amongst other things I’ve decided that Short John Silver’s gunports are just too ugly, being basically ‘faux’ ports made by sticking black paper onto the painted hull. See what I mean?

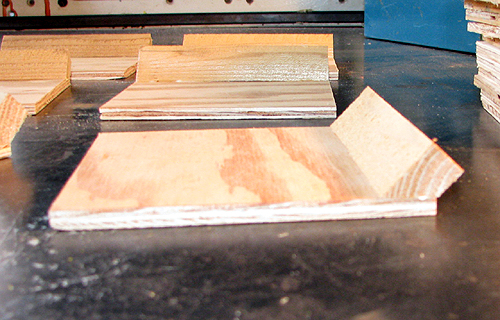

I spent today prepping new gunports that will include new hatch covers that will appear to be flipped back, exposing little stubby (black PVC) gun barrels. Can’t have anything too long or folks will bash into ’em so I’m making them more like bas-relief dioramas. Here’s a shot of the twelve hatches, which measure 5″ x 5″:

And here’s a shot of the first piece to be glued on. Tomorrow I’ll bore a hole in the plywood, insert a short piece of PVC and then attach the “hatch cover” to the wedge to complete the assembly.

In other news I’m busy soldering up EL wire to replace the broken bits that have accumulated over time. I’ve got plenty of the yellow on hand but I’m going to orger a bunch of green (sea grass) and some other colors (fauna to go with the subsea flora). Combining my order with those of Heidi and Gothalot we should qualify for the bulk price break and the Burner price break too. Oh, and thumbnails aren’t quite lined up with text because I have yet to figure out how to make that happen! More later..